Modified Cars Off-Road Vehicles Suspension Springs Manufacturers

1. Advantages of off-road vehicle modified suspension springs

High-strength load-bearing capacity: Our off-road vehicle suspension springs are designed to withstand high loads, impacts, and stresses in terrains, ensuring performance on mountain roads, deserts, and muddy and uneven roads.

Enhanced durability and fatigue resistance: Made of high-quality high-strength steel, after special heat treatment, it has strong corrosion resistance and fatigue resistance, ensuring long-term performance in harsh environments.

Excellent shock absorption and comfort: The special spring design and material enable the spring to effectively absorb road bumps, reduce the impact on the vehicle body, improve driving comfort, and provide a smooth driving experience even in off-road conditions.

Customized design: According to the customer's off-road needs and vehicle models, we provide professional customization services, and accurately adjust the hardness and length of the suspension springs to optimize the overall performance of the suspension system.

Improve handling and stability: The optimized spring design can provide better vehicle handling, ensure that the vehicle has a stronger grip and stability in complex terrain, and improve driving safety.

2. Advantages of road car modified suspension springs

Superior handling and stability: Our road car suspension springs are precisely designed to effectively control the height and posture of the vehicle body, improve stability when driving at high speeds, and ensure that the driver has a handling experience under various road conditions.

Balanced comfort and performance: The hardness and elasticity of the springs are carefully adjusted to absorb small-scale road vibrations to ensure comfort, and provide sufficient support to ensure the stability of the vehicle when driving on curves and at high speeds.

Optimized aerodynamic performance: In order to reduce wind resistance and improve the overall performance of the vehicle, our road car suspension springs are specially designed to effectively reduce the changes in the body posture and improve aerodynamic stability during driving.

Durability and high performance: Using high-quality spring materials and advanced heat treatment processes provides higher durability and fatigue resistance, reduces maintenance frequency, and provides long-term and stable performance support for car owners.

Precise tuning and personalized customization: According to customers' requirements for driving experience, we provide personalized tuning services, and can accurately adjust the suspension springs according to the model, driving style, and road conditions to ensure the driving performance.

3. Comprehensive advantages of manufacturers

Advanced production technology: The company adopts advanced production equipment and technology to ensure that each suspension spring meets precision and quality standards.

Strong R&D capabilities: With many years of industry experience and a professional R&D team, we are able to continuously innovate and optimize product design based on market demand and customer feedback.

Comprehensive quality control: From raw material selection to the production process, every link is strictly controlled to ensure that each product is rigorously tested and meets high-quality standards.

Strong after-sales service support: Provide a complete after-sales service system, including technical consultation, product installation guidance, and long-term product warranty, so that customers have no worries.

-

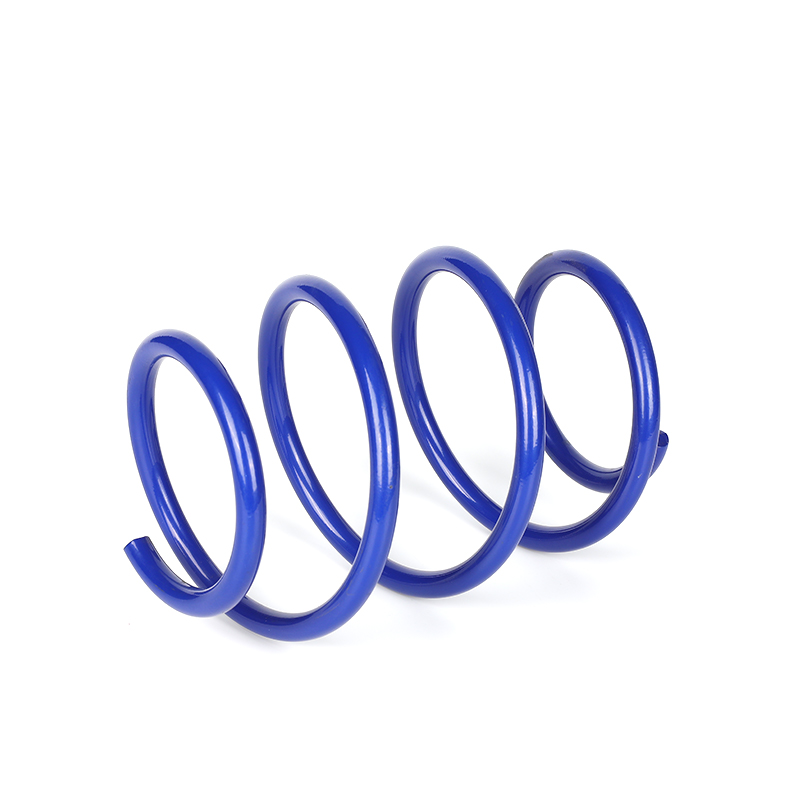

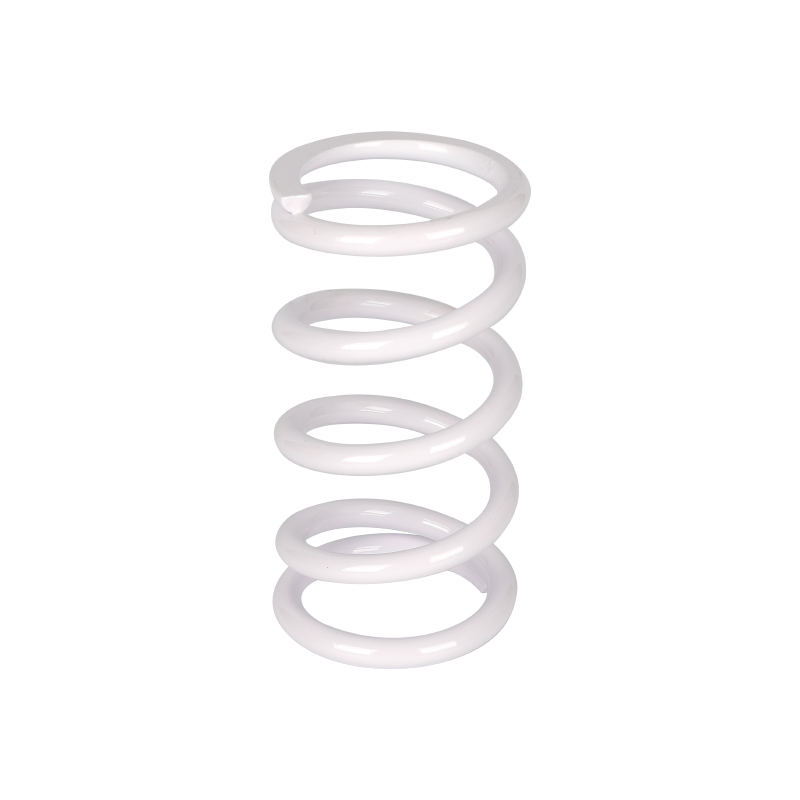

Modified car suspension spring

-

Modified car suspension spring

-

Modified car suspension spring

-

Modified car suspension spring

-

Modified car suspension spring

-

Modified car suspension spring

-

Modified car suspension spring

-

Modified car suspension spring

-

Modified car suspension spring

-

Modified car suspension spring

-

Modified car suspension spring

About Us

Certificate

-

IATF 16949:2016

IATF 16949:2016

Latest News

-

Knowledge 2026-02-07

Car suspension systems are vital components designed to enhance ride comfort and ensur...

Read More -

Knowledge 2026-01-31

Car Suspension Springs play a crucial role in maintaining vehicle stability, ride comf...

Read More -

Knowledge 2026-01-23

Car suspension springs are essential components in vehicle suspension systems, designe...

Read More -

Knowledge 2026-01-16

Car Suspension Springs are a critical component of any vehicle’s suspension system, di...

Read More -

Knowledge 2026-01-09

Car Suspension Springs play a crucial role in vehicle performance, safety, and comfort...

Read More

-

Automobile Suspension Spring

Automobile Suspension Spring

1. Our automotive suspension springs are made with advanced manufacturing technology and are precisely designed to ensure smooth d...

-

Modified Car Suspension Spring

Modified Car Suspension Spring

1. Advantages of off-road vehicle modified suspension springsHigh-strength load-bearing capacity: Our off-road vehicle suspension ...

-

Brake Spring

Brake Spring

1. Brake springs play an important role in ensuring the stability of the brake chamber and brake system.Precision manufacturing an...

Contact Us Now

Modified Cars Off-Road Vehicles Suspension Springs Industry knowledge

Can Modified Cars Off-Road Vehicles Suspension Springs Boost Fuel Efficiency?

As global fuel prices remain volatile and environmental regulations tighten, the automotive aftermarket industry is exploring innovative ways to improve vehicle efficiency. One emerging debate centers on whether upgrading suspension systems—specifically through high-performance springs—can enhance fuel economy. Leading spring manufacturer Zhejiang Zongheng Spring Co., Ltd. has entered this conversation with cutting-edge solutions designed for modified off-road vehicles.

The Science Behind Suspension and Fuel Efficiency

Traditional suspension systems prioritize durability and comfort, but their weight and energy absorption characteristics may inadvertently increase fuel consumption. Modified suspension springs, however, leverage advancements in material science and structural design to reduce energy loss during operation. By minimizing unnecessary oscillations and optimizing load distribution, these springs help maintain smoother vehicle dynamics, which in turn reduces engine strain.

Zhejiang Zongheng Spring Co., Ltd. has focused on developing high-strength, lightweight suspension springs using premium alloys and precision manufacturing. Their products undergo rigorous testing via spectrometers, fatigue testing machines, and multi-functional impact testers to ensure consistent performance under extreme conditions. This focus on reducing component mass while maintaining structural integrity directly aligns with fuel efficiency goals.

Case Study: Off-Road Vehicles

Off-road vehicles, known for their heavy-duty suspensions, present a unique challenge. Standard springs often add significant weight and generate excessive friction during articulation, forcing engines to work harder. Zhejiang Zongheng’s suspension springs address this through:

Lightweight Design: Advanced coiling techniques reduce spring mass by 15–20%, lowering overall vehicle weight.

Optimized Energy Transfer: Proprietary heat treatment processes enhance elasticity, reducing energy dissipation during compression and rebound.

Fatigue Resistance: Extended service life minimizes frequent replacements, indirectly cutting resource waste.

Field tests by independent mechanics suggest that upgraded springs can improve fuel economy by 3–5% in off-road scenarios—a meaningful gain for enthusiasts and commercial operators alike.

Since its founding in 2021, the company has prioritized R&D in lightweight and high-fatigue-resistance technologies. Their production facility in Zhuji, Zhejiang, combines IATF/TS16949-certified processes with digital workflows to ensure precision and scalability. Our goal is to redefine suspension systems as efficiency enablers, not just durability components.

While suspension upgrades alone won’t transform fuel efficiency, they represent a critical piece of the puzzle. For off-road vehicle owners, investing in engineered springs from Zhejiang Zongheng offers a dual benefit: enhanced off-road capability and measurable fuel savings. As the industry shifts toward sustainability, such innovations underscore the potential of component-level engineering to drive broader environmental gains.

English

English 中文简体

中文简体 Deutsch

Deutsch Español

Español