Brake Chamber Springs For Trucks Manufacturers

1. Brake springs play an important role in ensuring the stability of the brake chamber and brake system.

Precision manufacturing and high performance: Our brake springs are made of high-quality alloy steel, and through special heat treatment and fine processing, ensure that the springs have high compressive strength and can maintain stable performance under various conditions.

Improve the stability of the braking system: The brake springs precisely adjust the elasticity so that the brake chamber can work quickly and stably, ensuring that the truck has a reliable response speed and effect during the braking process.

Optimized design: We provide a variety of specifications and design solutions for brake springs, which can meet the needs of different models and use environments, and ensure that the brake system can achieve the braking effect.

Long-lasting and durable: Our brake springs adopt an anti-fatigue design, high-pressure resistance, and corrosion resistance, reduce spring wear, extend its service life, and reduce maintenance costs.

2. Comprehensive advantages of manufacturers

Advanced production equipment and technology: We have introduced advanced production equipment and manufacturing technology from home and abroad to ensure the accuracy and consistency of products, improve production efficiency, and meet the needs of mass production.

Comprehensive quality management system: The company has a complete quality management system, and strictly produces and inspects in accordance with the IATF16949 quality standard. Each product undergoes multiple inspections to ensure reliable quality.

Strong R&D capabilities: We have an experienced R&D team that can continuously innovate technology and optimize product design based on market demand and customer feedback.

Customer customized services: We provide a full range of customized services. We can provide customers with tailor-made product solutions for different models and different usage environments.

Complete after-sales service system: We provide customers with one-to-one technical support and after-sales service to ensure that every customer enjoys professional technical consultation and service support during use.

-

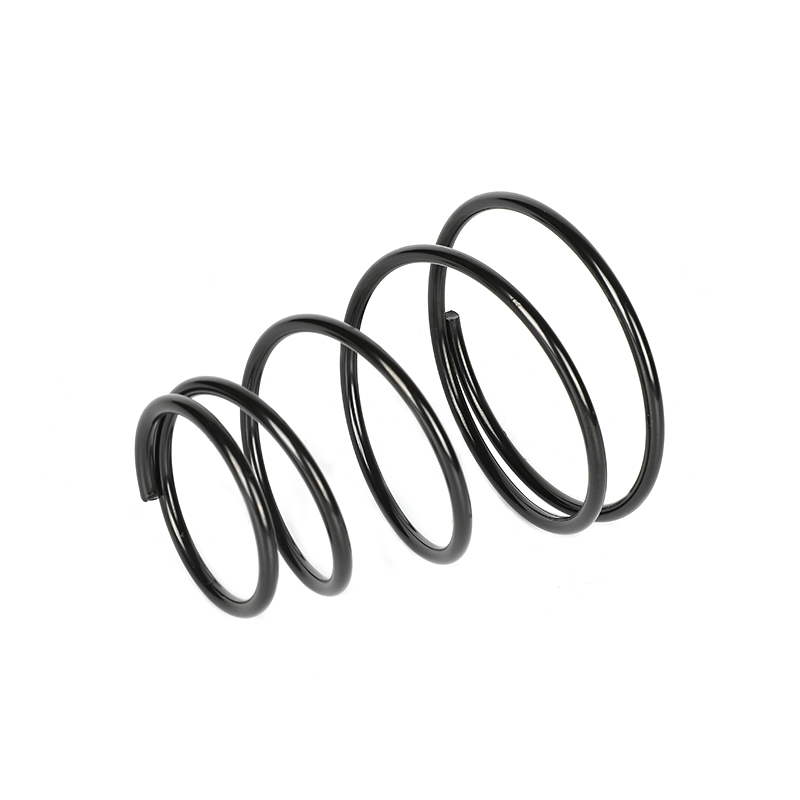

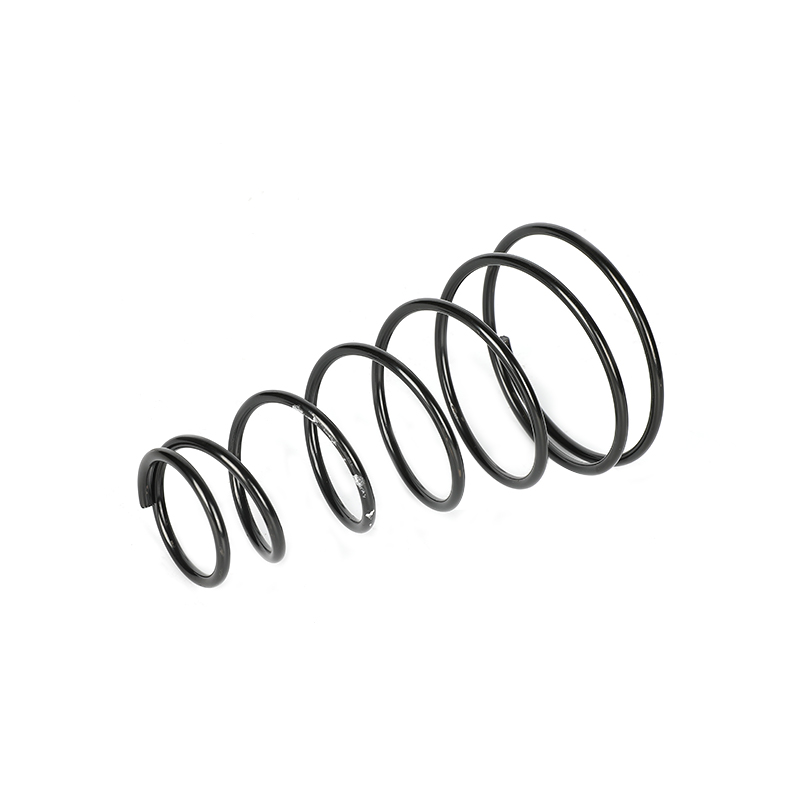

Brake spring

-

Brake spring

-

Brake spring

-

Brake spring

-

Brake spring

-

Brake spring

-

Brake spring

-

Brake spring

-

Brake spring

-

Brake spring

-

Brake spring

About Us

Certificate

-

IATF 16949:2016

IATF 16949:2016

Latest News

-

Knowledge 2026-02-07

Car suspension systems are vital components designed to enhance ride comfort and ensur...

Read More -

Knowledge 2026-01-31

Car Suspension Springs play a crucial role in maintaining vehicle stability, ride comf...

Read More -

Knowledge 2026-01-23

Car suspension springs are essential components in vehicle suspension systems, designe...

Read More -

Knowledge 2026-01-16

Car Suspension Springs are a critical component of any vehicle’s suspension system, di...

Read More -

Knowledge 2026-01-09

Car Suspension Springs play a crucial role in vehicle performance, safety, and comfort...

Read More

-

Automobile Suspension Spring

Automobile Suspension Spring

1. Our automotive suspension springs are made with advanced manufacturing technology and are precisely designed to ensure smooth d...

-

Modified Car Suspension Spring

Modified Car Suspension Spring

1. Advantages of off-road vehicle modified suspension springsHigh-strength load-bearing capacity: Our off-road vehicle suspension ...

-

Brake Spring

Brake Spring

1. Brake springs play an important role in ensuring the stability of the brake chamber and brake system.Precision manufacturing an...

Contact Us Now

Brake Chamber Springs For Trucks Industry knowledge

How Do Brake Chamber Springs For Trucks Affect Braking Performance?

In the commercial vehicle industry, braking performance is not just a matter of efficiency—it’s a critical safety imperative. Among the components that directly influence this performance, Brake Chamber Springs for Trucks play a pivotal yet often understated role. These springs are integral to ensuring consistent brake application and release, directly impacting vehicle safety, operational reliability, and long-term maintenance costs.

The Critical Role of Brake Chamber Springs

Brake chamber springs are the backbone of air brake systems in heavy-duty trucks. Their primary function is to convert compressed air energy into mechanical force, engaging the brake shoes against the drum during braking. Conversely, they must retract the shoes seamlessly when brakes are released. Any compromise in spring performance—whether due to material fatigue, improper tension, or structural defects—can lead to delayed braking response, uneven wear, or even catastrophic brake failure.

Key performance indicators for these springs include:

High Fatigue Resistance: Springs must endure millions of compression cycles without deformation.

Precise Load-Bearing Capacity: Consistent force output ensures predictable braking behavior.

Corrosion and Wear Resistance: Harsh operating environments demand durable surface treatments.

Engineering Excellence: The Zhejiang Zongheng Spring Co., Ltd. Approach

As a specialized manufacturer of brake system springs, Zhejiang Zongheng Spring Co., Ltd. has positioned itself at the forefront of innovation since its establishment in 2021. Located in Zhuji, Zhejiang—a hub for automotive components—the company combines advanced manufacturing capabilities with rigorous quality control to address the unique challenges of brake chamber spring production.

1. Material Selection & Process Precision

The company sources high-quality alloy steels from trusted global suppliers, ensuring optimal tensile strength and elasticity. Advanced coiling machines and heat treatment technologies (e.g., induction hardening) are employed to achieve precise spring geometry and metallurgical properties. This minimizes stress concentrations that could lead to premature failure.

2. Fatigue Life Optimization

With a dedicated R&D focus on high fatigue life, Zhejiang Zongheng utilizes cutting-edge testing equipment such as fatigue testing machines and spectrometers. These tools validate spring performance under simulated real-world conditions, ensuring compliance with international standards like IATF/TS16949.

3. Lightweight Design for Efficiency

By innovating in lightweight spring designs, the company reduces unsprung mass in brake systems—a critical factor in improving fuel efficiency and reducing component wear.

Why Quality Matters: The Ripple Effect of Subpar Springs

Case studies reveal that inferior brake chamber springs can lead to:

Increased Stopping Distances: Weak or inconsistent spring force delays brake engagement.

Asymmetric Braking: Uneven force distribution causes uneven pad wear and vehicle instability.

Costly Downtime: Frequent replacements disrupt fleet operations and inflate maintenance budgets.

Zhejiang Zongheng mitigates these risks through its vertically integrated production process. From raw material inspection to final shot blasting and surface coating, every batch undergoes stringent testing via equipment such as online flaw detectors and image analyzers. This ensures traceability and consistency—a non-negotiable requirement for global OEMs and aftermarket suppliers.

In an industry where milliseconds and millimeters matter, Brake Chamber Springs for Trucks are the unsung heroes of road safety. Manufacturers like Zhejiang Zongheng Spring Co., Ltd. exemplify how technological innovation, combined with disciplined quality management, can elevate braking performance to meet modern demands. For fleet operators and vehicle manufacturers, prioritizing springs engineered for strength, longevity, and precision isn’t just a choice—it’s a responsibility.

English

English 中文简体

中文简体 Deutsch

Deutsch Español

Español