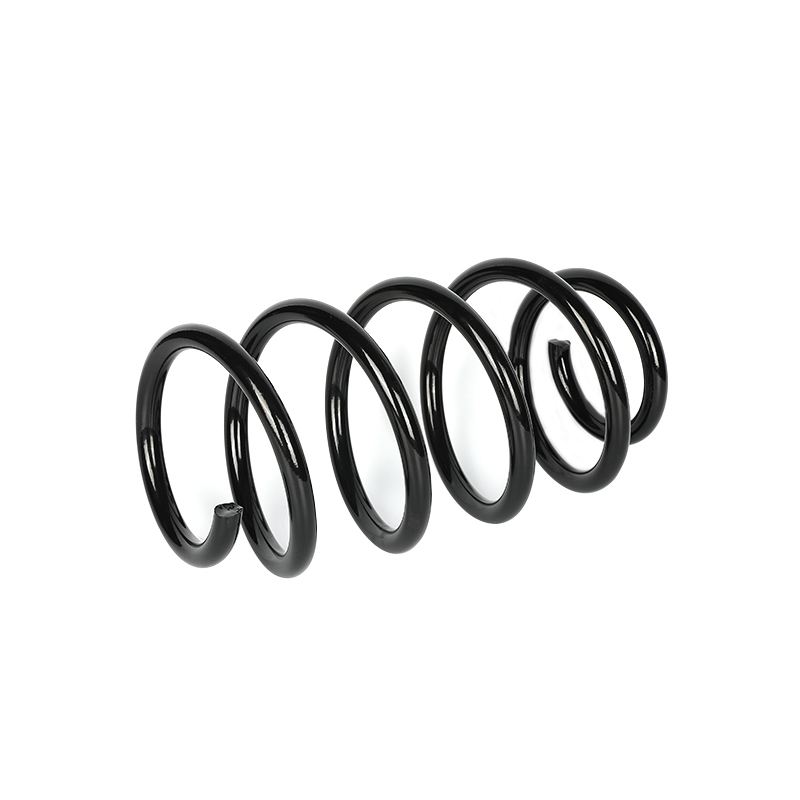

OE Replacement Car Suspension Springs Manufacturers

1. Our automotive suspension springs are made with advanced manufacturing technology and are precisely designed to ensure smooth driving and handling of the vehicle under various road conditions. They provide support in shock absorption, load bearing, and stability, and enhance the comfort and safety of the vehicle.

2. Technical features

Material selection: High-strength steel or alloy materials are used, which have stronger fatigue resistance and durability.

Precision manufacturing: Modern production technology is used to ensure the accuracy and consistency of each spring and its long-term performance stability.

Corrosion resistance: The surface is specially treated to enhance rust and corrosion resistance and extend the service life of the product.

Compression resistance: The spring is reasonably designed and can withstand large loads, while effectively absorbing shocks and improving the handling stability of the vehicle.

3. Product advantages

Improved comfort: Our suspension springs can effectively reduce road vibrations and enhance driving comfort.

Safety guarantee: High load capacity and elasticity enable the vehicle to maintain good stability at high speeds and complex road conditions.

Strong durability: High-quality materials and advanced technology are used to ensure good performance after long-term use.

Customized service: Provide customized solutions according to different models and customer needs to ensure the match.

4. Product application

Widely applicable to various models such as sedans, SUVs, trucks, buses, etc., to meet the personalized needs of different customers.

5. After-sales service

Provide comprehensive technical support and product warranty services to ensure that you have no worries during use.

-

Automobile suspension spring

-

Automobile suspension spring

-

Automobile suspension spring

-

Automobile suspension spring

-

Automobile suspension spring

-

Automobile suspension spring

-

Automobile suspension spring

-

Automobile suspension spring

-

Automobile suspension spring

-

Automobile suspension spring

-

Automobile suspension spring

About Us

Certificate

-

IATF 16949:2016

IATF 16949:2016

Latest News

-

Knowledge 2026-02-07

Car suspension systems are vital components designed to enhance ride comfort and ensur...

Read More -

Knowledge 2026-01-31

Car Suspension Springs play a crucial role in maintaining vehicle stability, ride comf...

Read More -

Knowledge 2026-01-23

Car suspension springs are essential components in vehicle suspension systems, designe...

Read More -

Knowledge 2026-01-16

Car Suspension Springs are a critical component of any vehicle’s suspension system, di...

Read More -

Knowledge 2026-01-09

Car Suspension Springs play a crucial role in vehicle performance, safety, and comfort...

Read More

-

Automobile Suspension Spring

Automobile Suspension Spring

1. Our automotive suspension springs are made with advanced manufacturing technology and are precisely designed to ensure smooth d...

-

Modified Car Suspension Spring

Modified Car Suspension Spring

1. Advantages of off-road vehicle modified suspension springsHigh-strength load-bearing capacity: Our off-road vehicle suspension ...

-

Brake Spring

Brake Spring

1. Brake springs play an important role in ensuring the stability of the brake chamber and brake system.Precision manufacturing an...

Contact Us Now

OE Replacement Car Suspension Springs Industry knowledge

Are OE Replacement Car Suspension Springs Safer for Daily Driving?

With the increase in the number of cars, consumers are increasingly concerned about vehicle safety and component quality. In the key area of suspension systems, the safety of OE Replacement Car Suspension Springs has become a hot topic.

The core advantage of OE Replacement springs: compliance and consistency

OE Replacement Car Suspension Springs strictly follow the original design standards, and their dimensions, material parameters and mechanical properties are fully matched with the vehicle's factory configuration. Take Zhejiang Zongheng Spring as an example. The company has passed the IATF/TS16949 international quality management system certification and adopts a digital production process and 6S management model throughout the process from raw material procurement to finished product delivery. Its suspension springs are made of high-quality alloy steel from home and abroad, combined with high-precision coiling machine forming, controlled atmosphere heat treatment and multi-pass shot peening strengthening process to ensure that the yield strength and fatigue life of each batch of products meet the original design requirements.

Behind safety: reliability supported by laboratory data

The failure of suspension springs may directly lead to vehicle control instability. Zhejiang Zongheng Spring's laboratory is equipped with spectrometers, online flaw detectors, fatigue testing machines and other equipment, which can conduct full-dimensional testing of the spring's chemical composition, internal defects and long-term load performance. For example, its fatigue testing machine can simulate the spring's ability to withstand more than 1 million cyclic loads under extreme road conditions, while the lateral force load tester verifies the spring's anti-deformation performance under complex stress. These data not only meet the OEM standards, but even achieve technological excellence in some high-strength and lightweight fields.

Why choose a professional OE Replacement supplier?

Non-original springs may sacrifice materials or processes due to cost compression, leading to premature aging or fracture risks. In contrast, compliant companies such as Zhejiang Zongheng Spring reduce costs through large-scale production and digital management, while adhering to the "high fatigue life" research and development direction. Its suspension springs use a multi-functional sand and gravel impact tester to verify the corrosion resistance of the surface coating, and use an image analyzer to ensure that the product's geometric accuracy is controlled within ±0.1mm, so as to adapt to the dynamic characteristics of the suspension system of different models.

Consumer Decision Guide: Pay attention to certification and test reports

Experts suggest that when purchasing OE Replacement Car Suspension Springs, you should give priority to suppliers with IATF/TS16949 certification and ask for product test reports to confirm their performance parameters. Taking Zhejiang Zongheng Spring as an example, each batch of springs can provide a complete data chain including fatigue life, tensile strength and metallographic structure analysis to help users clearly understand the product characteristics.

Overall, OE Replacement Car Suspension Springs produced in compliance with the original factory can provide reliable safety protection for daily driving with consistent performance standards and strict quality control processes. Companies like Zhejiang Zongheng Spring are promoting the industry to develop in a higher strength and lighter direction through technological innovation and quality management, providing global car owners with solutions that are both cost-effective and safe.

English

English 中文简体

中文简体 Deutsch

Deutsch Español

Español